Carding 4 Carders

Professional

- Messages

- 2,724

- Reaction score

- 1,586

- Points

- 113

The world's first 3D-printed rocket nozzle has been successfully tested.

NASA has successfully tested a rocket nozzle printed on a 3D printer made of a new weldable type of aluminum. This step was taken in order to increase the payload capacity for missions to deep space.

The importance of mass for spacecraft cannot be overemphasized. Aluminum, due to its low density, is almost at the top of the list of ideal materials for creating strong and lightweight components. However, aluminum does not tolerate high temperatures and often cracks during welding. A traditional rocket nozzle can consist of thousands of separately welded parts.

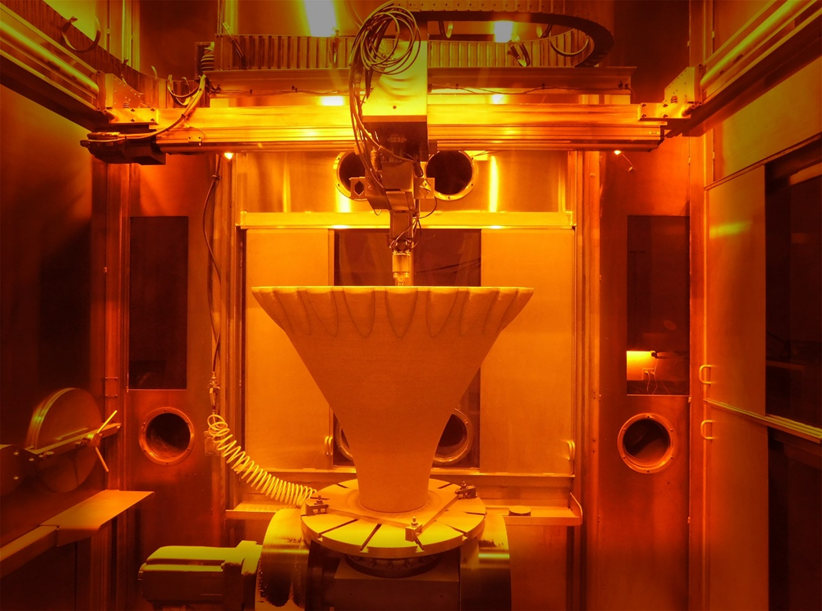

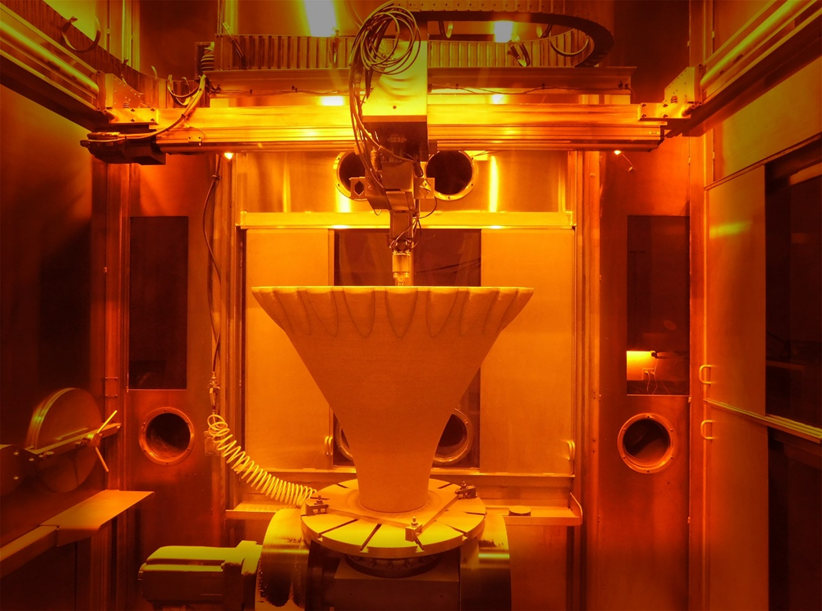

Rocket nozzle in a 3D printer

The RAMFIRE (Reactive Additive Manufacturing for the Fourth Industrial Revolution) project, funded by the NASA Space Technology Mission Directorate (STMD), was created to solve this problem. As part of the project, engineers developed lightweight aluminum nozzles with internal cooling channels to prevent melting. The researchers also used a new aluminum variant called A6061-RAM2.

RAMFIRE project researchers said the technology allowed them to shorten the manufacturing process steps and create large engine parts in a matter of days. The technological breakthrough will be used as a basis for future developments. Two such nozzles have already passed multiple tests with liquid oxygen and hydrogen, demonstrating high efficiency.

www.youtube.com

www.youtube.com

3D printing of rocket components is becoming increasingly popular in the space industry. Rocket Lab, for example, already has the world's first 3D-printed Rutherford engine, and Britain's Skyrora also plans to use 3D printing for its engines.

However, it is worth noting that the introduction of such technology requires serious investment in design, equipment and materials. However, this approach can radically speed up and reduce the cost of production in the future.

NASA has successfully tested a rocket nozzle printed on a 3D printer made of a new weldable type of aluminum. This step was taken in order to increase the payload capacity for missions to deep space.

The importance of mass for spacecraft cannot be overemphasized. Aluminum, due to its low density, is almost at the top of the list of ideal materials for creating strong and lightweight components. However, aluminum does not tolerate high temperatures and often cracks during welding. A traditional rocket nozzle can consist of thousands of separately welded parts.

Rocket nozzle in a 3D printer

The RAMFIRE (Reactive Additive Manufacturing for the Fourth Industrial Revolution) project, funded by the NASA Space Technology Mission Directorate (STMD), was created to solve this problem. As part of the project, engineers developed lightweight aluminum nozzles with internal cooling channels to prevent melting. The researchers also used a new aluminum variant called A6061-RAM2.

RAMFIRE project researchers said the technology allowed them to shorten the manufacturing process steps and create large engine parts in a matter of days. The technological breakthrough will be used as a basis for future developments. Two such nozzles have already passed multiple tests with liquid oxygen and hydrogen, demonstrating high efficiency.

RAMFIRE Nozzle Hot Fire Test

The RAMFIRE nozzles complete hot fire testing at Marshall’s East test area using liquid oxygen and liquid hydrogen (orange/clear plume), as well as liquid ox...

3D printing of rocket components is becoming increasingly popular in the space industry. Rocket Lab, for example, already has the world's first 3D-printed Rutherford engine, and Britain's Skyrora also plans to use 3D printing for its engines.

However, it is worth noting that the introduction of such technology requires serious investment in design, equipment and materials. However, this approach can radically speed up and reduce the cost of production in the future.